STYLE AND CUSTOMIZATION

Custom-made creations for high-end awards

Custom-made creations for high-end awards

Our company has always been a point of reference in the field of corporate awards.

Thanks to the experience gained by making awards for important business realities, LAMP has specialized in the creation of customized products according to the specific needs of the customer.

The development of new techniques and manufacturing technologies allowed us to implement the offer by combining the historical core of the company, which offers a wide range of conied and luxury customized products, with a new concept of awarding, focused on high quality design and manufacturing, supported by the use of jewelry techniques.

Thanks to the investments in research and development of our prototyping and design department, we are able to offer to our Clients custom-made products, studied and created for the enhancement of corporate brands.

Once the target and the construction requirements of the Client have been defined, the ability to evaluate and analyze the specifications to be satisfied is a fundamental part of the production process.

Our production manager, working with the customer, supervises all the production phases:

Must haves of every corporate awarding, LAMP products, such as medals and badges, stand out from standardized contexts thanks to the use of coining techniques, ie the compression of metal between two tempered steel cylinders.

Completing the wide range of processing offered by LAMP, the engravings made by milling or with a diamond tip allow the personalization of the single product.

Given the increasing requests by companies for valuable alternatives to classic corporate awards, LAMP has developed a sector dedicated to the creation of customizable branded products, designed to go beyond the usual concept of company award. We turned to everyday objects, revisiting them in terms of style, designed and created by combining traditional techniques with the jewelry skills of our technicians. Exploiting three-dimensionality and games of depth, combining the goldsmith techniques with the company know-how, LAMP’s creations are enriched by the collaboration with the training agency E. Ghirardi, a high education goldsmith school present in the Turin area since 1904.

Thanks to the support of our Packaging sector, the awarding division complete its offer with luxury packaging, designed and manufactured to meet the needs and peculiarities of our customers’ awards.

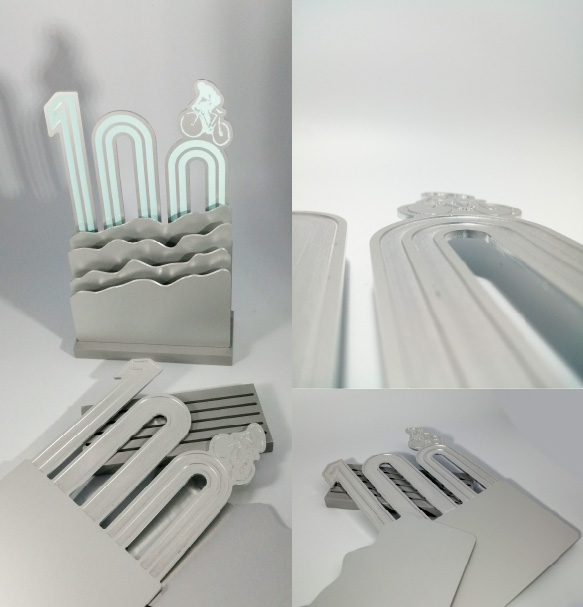

Passion and decades of experience, combined with skills and competence, make LAMP a point of reference for the sports awards field. Medals, cups and plaques acquire new value thanks to the use of quality materials, finishes and customization techniques designed to fully satisfy the customer’s needs. The high specialization in the realization of prizes and trophies unique in their kind, made by design and personalized, finds its natural place in elite sporting realities.

Trophy made of silver anodized aluminum, composed of six elements.

The charm of classic awards, revisited in design and materials thanks to the use of new techniques and manufacturing technologies acquired by our company in decades of activity, is enriched by customizations and finishes designed for the realization of ad hoc awards.

Dimensions and shapes will be decided on request, after acquiring the files or designs.

The thickness will be subsequently based on the kind of metal and our clients requests.